| |

|

|

|

|

|

| S.No |

Description |

Material |

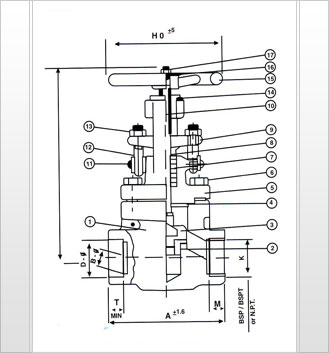

1. |

Body |

ASTM A 105 |

2. |

Seat Ring |

S.S. AISI 410 (HARDENED) |

3. |

Disc |

S.S. AISI 410 (HARDENED) |

4. |

Gasket |

S.S. 304, Spiral Wound Metallic With CAF |

5. |

Bonnet |

ASTM A 105 |

6. |

Bonnet Bolt |

ASTM 193 Gr. B7 |

7. |

Gland Packing |

Metallic Wire Reinforced Graphited Asbestos |

8. |

Gland |

S.S. AISI 410 |

9. |

Gland Flange |

ASTM-A-105 |

10. |

Spindle |

S.S. AISI 410 / Carbon Steel |

11. |

Rivet |

Carbon Steel |

12. |

Washer |

Carbon Steel |

13. |

Eye Bolt & Nut |

S.S. AISI 410/ Carbon Steel |

14. |

Yoke Sleeve |

NI-Resist/S.G. Iron / C.S. |

15. |

Handwheel |

Malleable Iron |

16. |

Washer |

Carbon Steel |

17. |

Handwheel Nut |

Carbon Steel |

|

|

| |

|

|

|

| |

|

|

|

Socket Weld End |

Screwed End |

Size 'NB' |

'A' |

'B' |

'D' |

'T' |

'K' |

'M' |

'H' |

'L' |

8mm |

74 |

3.2 |

14.1 |

9.5 |

¼ “ |

10.5 |

89 |

145 |

10mm |

74 |

6 |

17.5 |

9.5 |

3/8“ |

10.5 |

89 |

145 |

15mm |

74 |

9 |

21.7 |

9.5 |

½ “ |

13.5 |

89 |

145 |

20mm |

90 |

12 |

27.1 |

12.7 |

¾ “ |

14 |

89 |

154 |

25mm |

100 |

17.5 |

33.8 |

12.7 |

1” |

17.5 |

89 |

173 |

3mm |

122 |

22.5 |

42.5 |

12.7 |

1¼” |

18.5 |

146 |

240 |

40mm |

122 |

29.5 |

48.6 |

12.7 |

1½” |

18.5 |

146 |

240 |

50mm |

140 |

35 |

61.1 |

16 |

2” |

19 |

146 |

245 |

|

|

| |

|

| |

|

|

|

| |

|

|

|

|

| |

|

|

|

| » |

Design Features: |

|

|

| |

----------------------------------------------------------------------------------------- |

|

|

- Manufacturing Standards-BS : 5352 / API 602

- Reduced Bore

- Socket Weld End As Per ANSI B 16. 11.

- Screwed Ends As Per ANSI B 2.1

- Testing As Per BS : 5146 / API 598

- Also Available In CLASS 900, 1500

- Available In Full Bore Up To Size 40 NB.

|

|

|

| |

|

|

|

| |

Class

|

Test Pressure |

HYDROSTATIC |

AIR |

BODY |

SEAT & BACK SEAT |

SEAT |

800 |

210Kg/cm2 |

141 Kg/cm2 |

6 Kg/cm2 |

|

|

|

| |

|

|

|

|

| |